Car Building with Ellis Capp

Ellis Capp ’19 is an engineering student at the University of Oxford from Modesto, California, who has worked on a variety of engineering projects since high school. In his free time, he enjoys car building and amateur rowing.

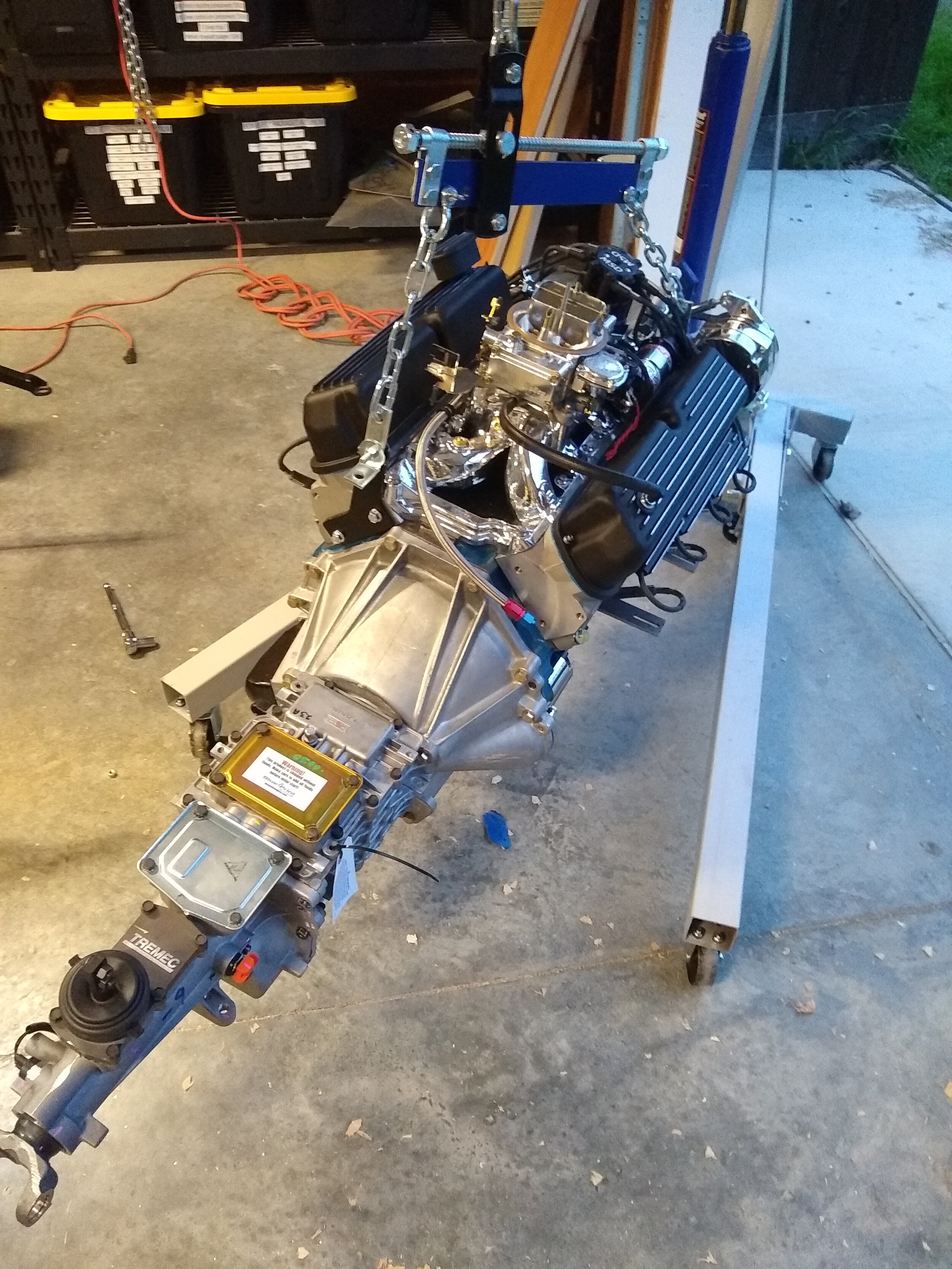

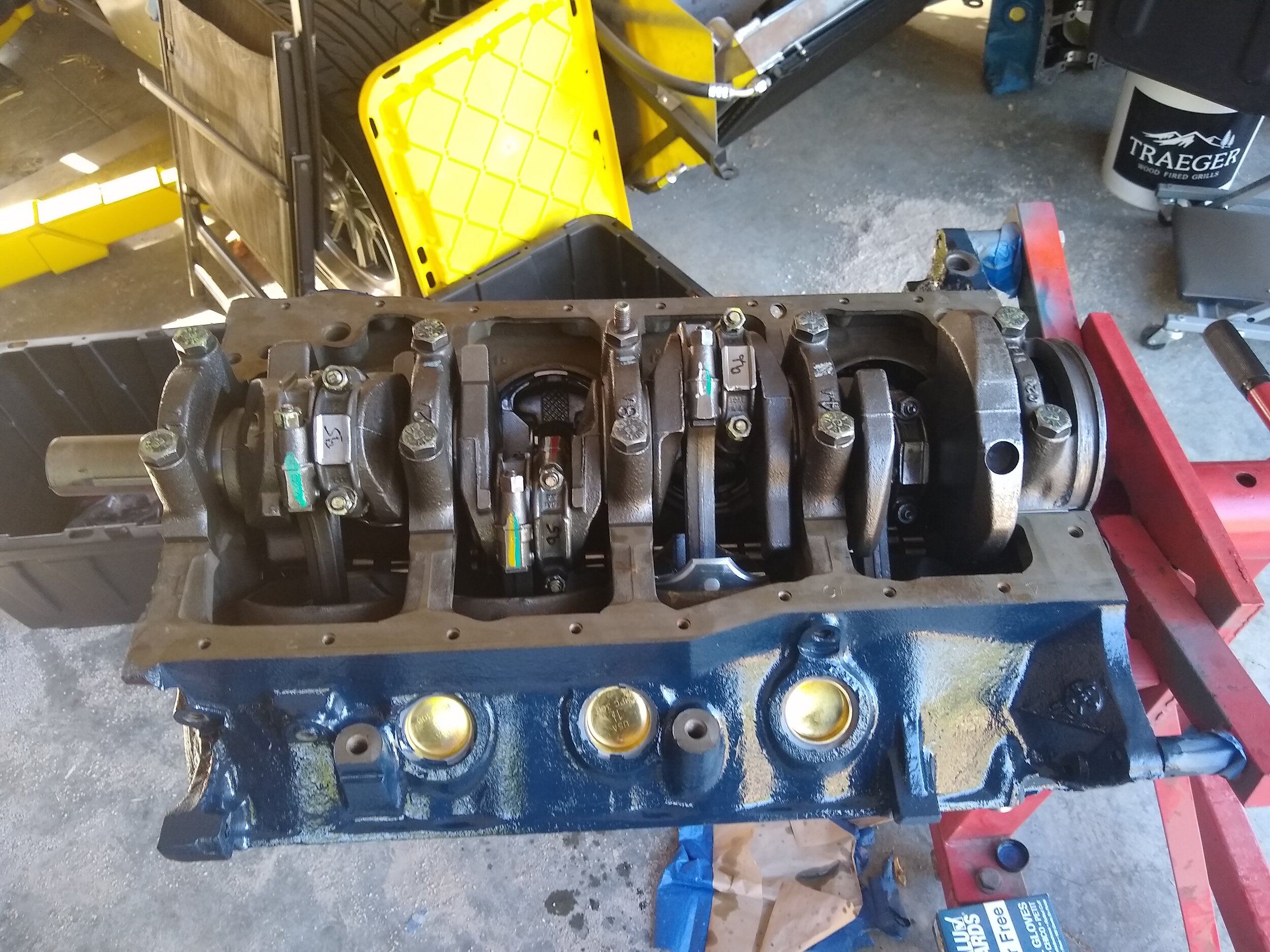

In the summer after his junior year, Ellis spoke with his older sister about how it might be fun to build a car from a kit. He began building the car in his senior year of high school, and it is still an ongoing project. Now, working on his kit car is a fun way for Ellis to spend time with his family. “Also, it’s just fun to be in a garage and turn bolts and make a giant, loud, fast creation,” Ellis shares.

He describes the process of building a car as “all-consuming,” saying that “building a car is like a thousand smaller projects.” When Ellis was in high school, “it was like putting the suspension onto the frame, putting the things that eventually house the wheels onto the frame, but the thing is that for like almost half the car’s life, there was not even an engine in it. So it’s a large undertaking for sure.” The process takes several years, and Ellis hopes that the car will be completed this year when he returns home from school.

In college, Ellis has taken on another car project through Formula Student (“Formula 1, but for undergraduates”), a yearly competition in the UK for teams of engineering students. He describes that “teams generally need several years just to get themselves off the ground and figure out how to build a car,” but until then, they compete in static events such as presentations about financials and engineering principles. The Oxford team—new as of a few years ago—was going to compete with their first competition car last year, but the plan did not materialize because of the pandemic.

Reflecting upon his experience building a car as part of a Formula Student team in comparison to his experience building a car in his garage, Ellis says that he would liken it to the difference between working as a small business and working as a corporation. “At home, the only [people] working on the car [are] me and members of my family. When some part needs to be added, I go drive myself to the hardware store, I pick up whatever bolts that they didn’t include in the kit. [...] I have free rein to drill holes in the chassis, et cetera,” Ellis shares. “Then we go to working on the car here, and this car has an extensive list of rules that it has to fulfill. You can only drill a hole in the chassis if you can structurally prove it’s not going to cause problems for you later. Whenever you want to buy a part, you need to ask the procurement officer first.” While the limitations of working on a large team can be frustrating, Ellis has found both building in his garage and building as part of a team to be valuable experiences.

Aside from car building, Ellis traveled to South Dakota this past summer (“where we got to sit 6 feet away from our extended family”). During his time there, his uncle, who is a “big maker,” taught Ellis and his cousin blacksmithing. Ellis made belt buckles, which turned into another project because “if you go on Amazon to look for a leather belt that has no buckle, you will not find anything that looks good.” When he returned home, he bought some leatherworking tools and learned to use them to make belts.

In his spare time, Ellis does amateur rowing, which he picked up in college as a way to get his exercise. He likes that he gets to work out with other people and expresses that though rowing makes him into an “ungodly early riser” during term, he enjoys watching the sun rise over the river.

During his time at OHS, Ellis took many of the physics classes, was involved in the robotics club in his sophomore and junior years, and started a FIRST Tech Challenge team at his local high school in his senior year.

Now, physics and engineering are still evidently a large part of his daily life as an engineering student. One key difference between OHS and college, though, is that he is now only studying engineering in college, following the UK system. “OHS definitely has a way of engendering [wanting to study multiple things] in people—I’m personally glad I can still write well,” Ellis shares. Unlike many of his peers from OHS, however, Ellis enjoys being able to focus on engineering, his subject of choice.

Ellis’s future plans are still tentative: “Sometimes I fantasize about working at Ford or some cool thing like that, or then other times, my mind flips and [I’m] like, maybe I want to go to grad school and learn how to make robotic arms that have soft robotic actuation.” In the meantime, though, Ellis plans to continue exploring internships in both the private and public sectors throughout college.

What advice does Ellis have for OHS students? “Just don’t procrastinate,” Ellis says. “If you can find the time—and if you don’t procrastinate, hopefully you should be able to—try to spend your spare time at OHS doing the things you enjoy. For me it was building cars, and then I showed up to an interview at Oxford and they were like, ‘Hey, you build cars. That’s pretty cool.’ Find something you enjoy that’s not just gaming or something. It’s good to have an outlet that helps you develop your personality.”